Heckler & Koch became famous and successful with a range of roller-delayed blowback small arms they manufactured from the early 1960’s up to the early 1990’s. So successful were these firearms that the name HK basically became synonymous with the roller-delayed blowback system. It may surprise some folks however to learn that HK did not in fact develop that system. The real story about its development took place over a decade and a half, and across 4 countries…

The seeds for this article were sewn a few weeks back a well-known Taiwanese airsoft company, LCTairsoft, asked me to assist their product development and marketing teams in launching of a new series of airsoft replicas. At the same time, the editor of the leading English-language airsoft magazine, Airsoft Action, asked me to write the first part of a review of the new LCT LK-33 airsoft replicas of the HK33 family of rifles. That review has been published now, check it out here. With this article I will take a more detailed look at the real-steel history than I was able to fit within the space possible in the magazine.

The story begins with an assault rifle developed by Mauser from late 1943 to early 1945 that was intended to replace the StG-44 and was labelled the StG-45(M). The StG-45 did not use a gas piston system like the StG-44, instead it utilized a recoil driven, roller-delayed blowback operating mechanism that was adapted from / inspired by the roller-locked system used on the famous MG-42 machine gun.

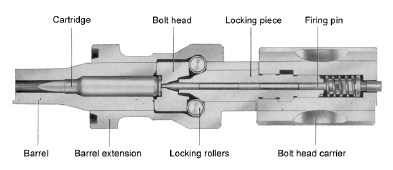

In the MG-42’s roller-locked system the bolt remained locked in place until the recoil booster on the muzzle end of the weapon pushed the barrel and barrel extension rearwards, and in so doing cammed the bolt and bolt-carrier out the locked position. The 3D animated video below illustrates this action clearly:

In seeking to adapt the roller-locked system of the MG42 to a rifle platform the engineers needed to make the system lighter in weight and simpler to manufacture. It also needed to operate with a fixed barrel for better accuracy. In so doing, they came up with the concept of a roller-delayed blowback system.

But getting the roller-delayed blowback mechanism to actually work as intended required an intensive amount of complex mathematical calculations and precision engineering. The system operates when there is enough energy to overcome the resistance of the rollers and drive the bolt back, but having also allowed the chamber pressure to drop to a safe level. If the system cycles too early the weapon can malfunction due to ruptured cartridge cases, and at worst could even injure the operator. On the other hand, if the system is delayed for too long then it won’t cycle at all.

One the key “Eureka!” moments for the designers was when they decided to cut shallow longitudinal grooves into the rifle’s chamber. This prevented the cartridge case from ‘sticking’ to the chamber when fired, and thereby enabled easier extraction of the spent case and more reliable cycling of the action. Once perfected, this roller-delayed blowback system was patented by Mauser’s Wilhelm Stähle and Ludwig Vorgrimler. The video below from Forgotten Weapons gives a good overview of how a modern roller-delayed mechanism functions.

The Wehrmacht Waffenamt (German Army Weapons Bureau) was sufficiently impressed by Mauser’s efforts that they type classified their new rifle as the StG-45(M) and ordered 30 prototypes for field testing. The war ended however before these StG-45s could be manufactured and most of the ones that exist today were assembled from their parts by captured Mauser engineers after the war.

The Mauser factory itself came under the jurisdiction of the French Occupation Forces and Mauser’s Department 37 development group, which had created the StG-45, was placed under control of the French War Department’s armament group, Direction des Etudes et Fabrication d’Armement (DEFA). In 1946 DEFA transferred the German engineers and equipment to the Mulhouse area of Alsace to a new facility that became known as the Centre d’Etudes et d’Armement de Mulhouse (CEAM) to work on developing new rifles for the French Army.

At CEAM the former Mauser engineers Ludwig Vorgrimler and Theodor Loeffler worked on furthering their development of the roller-locked, delayed blowback system. This culminated in their development of the CEAM Modèle 1950 assault rifle chambered for the US .30 cal. Carbine cartridge. The CEAM Modèle 1950 was trialed by the French Army but was abandoned when the French Armed Forces decided to focus on creating more traditional rifle designs that used the newly adopted full-power 7.62x51mm NATO cartridge.

After cancellation of the CEAM Modèle 1950 carbine, Ludwig Vorgrimler resigned and moved to Spain where he worked on small arms design for the state-owned design and development agency CETME (Centro de Estudios Técnicos de Materiales Especiales). This work led to the creation of the CETME Modelo 2 rifle in 1953, which was chambered for a proprietary 7.92x41mm round. The CETME rifle caught the eye of the recently formed West German Border Guards paramilitary force (Bundesgrenzschutz), but they requested that the rifle be modified to use the higher powered NATO 7.62x51mm cartridge.

Adapting the CETME Modelo 2 to fire the much more powerful 7.62x51mm NATO round was much more difficult than simply changing the barrel and bolt assembly – it would take a few years, and a complete redesign of the rifle. In the meantime, the Bundesgrenzschutz decided to purchase a version of the Belgian FN FAL – which they classified as the “Gewehr Eins” (G1). In November 1956 the newly-formed West German Army (Bundeswehr) also purchased several thousand FN-made G1s to equip its infantry units.

The Bundeswehr had however also been looking at the CETME rifle, and approached them about developing a 7.62x51mm NATO version that would meet German technical standards. This also gave CETME the motivation to produce a 7.6x51mm NATO version of the rifle for their domestic market too. This rifle, known as the CETME Modelo B, became the first full-production model and was adopted by the Spanish Army in 1957 as the CETME Modelo 1958.

When the Belgian government refused to allow the Germans to license manufacture the G1 locally, the Bundeswehr asked CETME for the rights to license manufacture the German-spec Modelo 58 rifle. After some international wheeling-and-dealing between the German, Dutch and Spanish governments, the Bundeswehr officially adopted the German-spec 7.62 NATO CETME rifle as the G3 in January of 1959.

Along comes Heckler & Koch…

In 1948 three other former Mauser engineers – Edmund Heckler, Theodor Koch, and Alex Seidel – salvaged what they could from the factory and started a new machine tool plant in the vacated Oberndorf premises that became known as the Engineering Office Heckler & Co. In December 1949, the Engineering Office Heckler & Co. changed its name and was registered officially as Heckler & Koch GmbH – manufacturing machine tools, bicycle and sewing machine parts, gauges and other precision components.

Within a few years however their attentions were turned once again to firearms and in 1956 Heckler & Koch responded to the West German government’s tender for a new infantry rifle for the Bundeswehr. When the G3 was adopted in 1959, Heckler & Koch were contracted by the Bundeswehr to be one of two manufacturers of the rifle.

From the early 1960s Heckler & Koch became almost entirely focused on developing firearms for the domestic and international military, law enforcement, and sport markets and grew to become one of the world’s largest and most well-known small arms companies. Key to the company’s success was the roller-delayed blowback system which they placed at the heart of a wide range of battle proven rifles, sub-machine guns and machine guns (see illustration below).

HK’s roller-delayed blowback system would go on to be used in all of the company’s military and civilian selective-fire and semi-auto only firearms throughout the 1960’s, 1970’s, and 1980’s – eventually being officially dropped in the 1990’s when HK switched over to short-stroke gas piston mechanisms for platforms such as the XM-8, G-36, HK-416, G-28, G-95, and beyond…

Epilogue:

Although its operating system dates back to the end of the Second World War, and the G3 rifle design to the 1950’s, the platform continued to soldier on up until recent years – due to its reliability, and the range and punch delivered by its powerful 7.62x51mm round.

That time when the US Army might have adopted an HK roller-delayed, blowback, operated machine gun… Unfortunately, HK was a late entry to the US Army’s Squad Automatic Weapon trials and we unable to deliver a solution in time that addressed all of the program requirements – specifically, the ability to interface with the standard US Army MG tripod, ability to accept STANAG M16 magazines, and it also lacked a plastic container for the 250-round ammo belt specified. The tripod adapter and plastic ammo carrier would probably have been an easy fixes, but the ability to accept STANAG magazines was a bigger challenge… (for more on that story, see our article: HK Cold War Light Machine-guns)

**********

Footnote: While Eugene Stoner and Mikhail Kalashnikov are justifiably famous names in the history of post-WWII firearms design, perhaps it is high time that Ludwig Vorgrimler and Theodor Loeffler receive the recognition that they deserve as well.