Those wizards at Dave’s Custom Airsoft Ltd. have done it again! First they created the world’s best (and only?) full authentically detailed replica of the HK21 machine-gun, now they’ve converted a G&G MG42 replica into a stunning rendition of the modernized and upgraded MG3-KWS (Kampfwertsteigerung / “Combat Improved”) developed by Rheinmetall and Tactics Group.

In their own words, here is the story:

This 12kg full Steel MG3 KWS started life as a fantastic G&G MG42. We 100% disassembled this machine gun, sandblasted all of the steel parts back to a smooth finish. After sandblasting we cut steel 20mm rail sections and welded them to the weapon using real steel images for reference. We also welded up the rear sight block to remove the hole seen on MG42 but not on MG3 KWS, as well as this we lowered the height at which the sight block sat for the same reason. For the top cover we flattened the front top section to accept a steel 20mm rail section and created a steel block spacer at the rear which we bolted and welded together. We modified the shape of the feed tray above the bullet belt by cutting out the original MG42 section and replacing it with bent sheet steel 2mm in thickness.

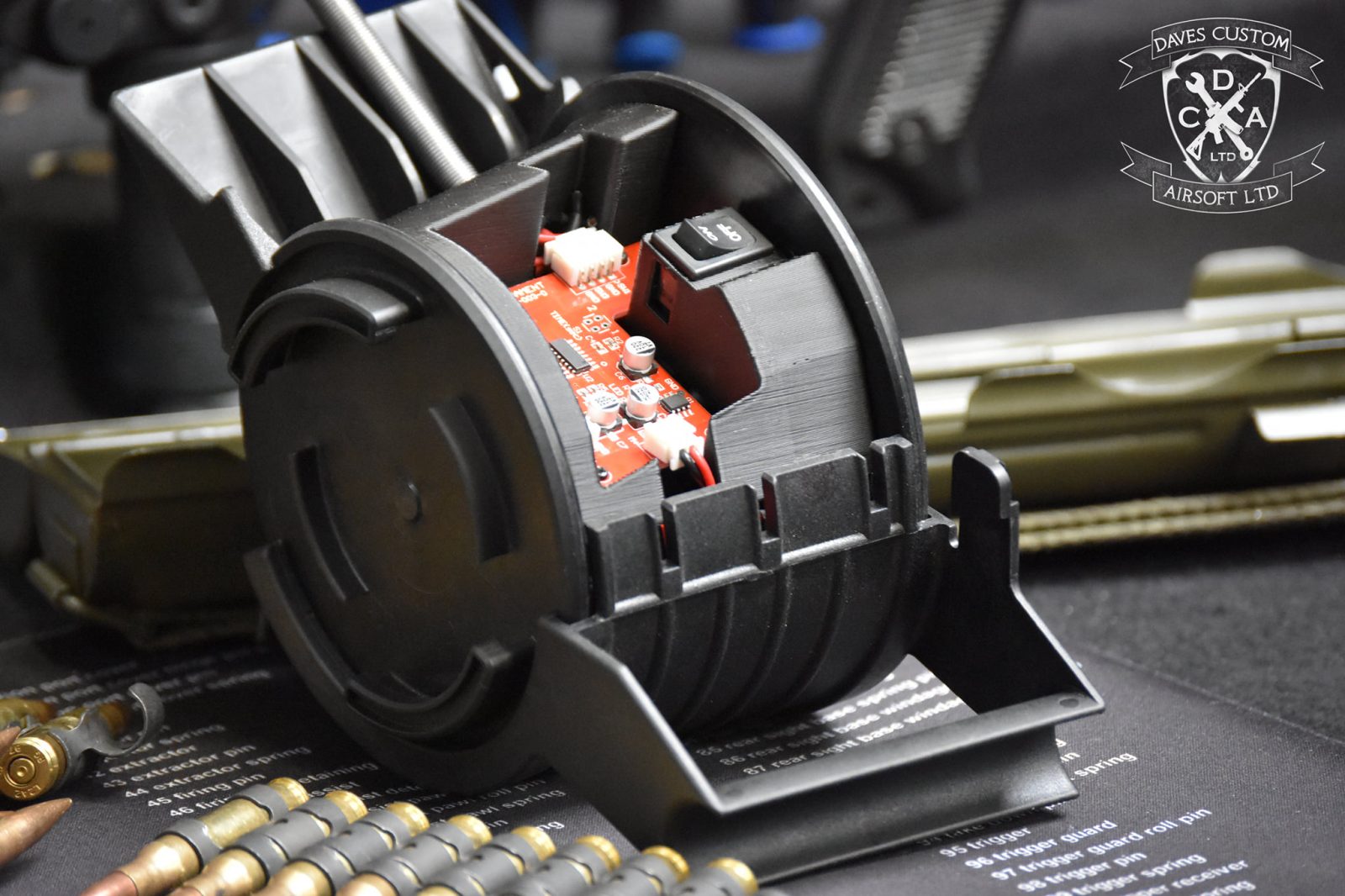

In order for us to use a real steel trommel or belt box we needed a real MG3 feed tray which has a push button release to remove the belt box. This required heavy modification in order to clear the gearbox and we again welded cross members to add structural support to this vital part once it was cut to the required shape. The Belt box / trommel itself is a HK original and we designed a 3D printed insert with the help of DTD that allowed for the G&G MG42 drum magazine electric internals to fit in, there is space for the usual battery inside, and, the insert can be removed from the magazine for maintenance. The best thing about the trommel is that the original design allows for a sliding door which we utilised to enable the firer to feed BBs into the magazine whilst in game.

For the carry handle we designed a 3D printed prototype, which we then had 3D printed in stainless steel. We then drilled and tapped the weapon and used M8 bolts to ensure that the bi-pod remains strong, the handle folds up and down with no play so that it does not wobble and will rest in a given position desired by the user. The grip parts of the carry handle mechanism were also professionally 3D printed for the highest quality finish.

We replaced the MG42 wooden pistol grips with real steel MG3 grips that we had imported from the USA, some modification was required for fitting including slightly reshaping the section around the safety catch.

The stock was arguably the hardest part of this build, we designed the stock from scratch with an adjustable cheek rest, removable butt pad and integrated CAA monopod setup which locks in place fully up and tucked away, at 45 degrees down and also at 90 degrees down, it has an extendable spring loaded arm at the base which is adjustable by the shooter. This highly complex stock was 3D printed in house to provide a prototype and then 3D printed professionally for the highest quality finish.

Having all the parts we then Cerakoted every Steel part in Cerakote Graphite Black in order to allow the highest possible quality and most durable finish. In accordance with the real steel images we added an adjustable height 20mm mount and short dot scope setup which provides excellent eye relief and a natural, comfortable aim. This is easily one of the finest airsoft replicas ever produced!

This particular example has already sold to one of our fantastic customers in France and we thank him for his custom and for supporting us in our endeavors to make the very best airsoft replicas we can.

All for the mere price of £4,500.00

For further info, and photos, of this beautiful beast go to Dave’s Custom Airsoft